Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

Ever wondered how power transmission lines withstand lightning strikes? Surge arresters are the unsung heroes, protecting equipment from high-voltage spikes. These devices play a crucial role in safeguarding power transmission line equipment from electrical transients. In this post, you'll learn about surge arresters, their purpose, and their significance in maintaining system stability and preventing equipment failure.

A surge arrester is a device designed to protect electrical equipment from sudden, high-voltage spikes. These spikes, often caused by lightning strikes or switching operations in power systems, can damage or destroy sensitive components. The surge arrester works by diverting the excess voltage away from the equipment and safely directing it to the ground.

At normal operating voltages, the arrester remains inactive, providing no interference to the system. When a voltage surge occurs, it quickly becomes conductive, creating a low-resistance path that shunts the surge current to the earth. This action prevents the transient voltage from passing through and damaging the connected equipment.

Surge arresters typically consist of several critical components that enable their protective function:

Metal Oxide Varistor (MOV): This semiconductor component changes resistance based on voltage. Under normal voltage, it acts as an insulator. When voltage surges, its resistance drops sharply, allowing current to flow through it to ground.

Gas Discharge Tube (GDT): A sealed tube filled with gas that becomes ionized during high-voltage events, allowing current to pass and diverting the surge.

Thermal Fuses or Circuit Breakers: These safety devices disconnect the arrester if it overheats or fails, preventing fire hazards.

Enclosure: Provides physical protection and insulation for the internal components, ensuring durability and safety.

Some surge arresters combine these components to optimize performance. For example, MOVs provide fast response, while GDTs handle higher current surges but respond slightly slower. Together, they offer comprehensive protection.

Surge arresters serve a critical role in protecting electrical systems from sudden voltage spikes known as transients. These transients often arise due to lightning strikes nearby or switching operations in power systems. When such a surge occurs, it can cause severe damage to electrical equipment, leading to costly repairs or replacements.

The primary purpose of a surge arrester is to detect when voltage exceeds normal levels and then quickly divert this excess energy safely to the ground. By doing so, it prevents the high voltage from reaching sensitive components, which could otherwise be destroyed or degraded. This protection ensures the longevity and reliability of electrical devices, especially those in power transmission systems.

Unlike insulation or circuit breakers that protect against continuous overcurrent or faults, surge arresters specifically guard against transient overvoltages. They do not stop a direct lightning strike on a conductor but effectively manage induced surges caused by lightning nearby or switching events. This distinction is important because these transient events happen frequently in power systems and can cause cumulative damage over time.

In power transmission lines, surge arresters are strategically installed at points where conductors enter equipment, such as transformers or switchgear. They are connected both to the conductor and to the earth ground, creating a pathway for surge currents to be safely discharged. This setup ensures that any transient voltage is bypassed around the equipment rather than through it.

Power transmission lines often span long distances, making them vulnerable to induced surges from atmospheric electrical activity. Without surge arresters, these surges would travel along the lines and damage transformers, insulators, and other vital components. By installing surge arresters at both ends of a conductor, the system gains comprehensive protection against these transient events.

Moreover, surge arresters help maintain system stability and reduce downtime by preventing equipment failure. This is particularly crucial in high-voltage transmission networks, where outages can affect large areas and cause significant economic loss.

Surge arresters come in various types, each designed for specific voltage levels and applications in power systems. Understanding their differences helps in selecting the right arrester for protecting equipment effectively.

These arresters are used in low-voltage distribution systems, typically up to 1,000 volts. They protect electrical appliances and low-voltage transformer windings from transient overvoltages. Commonly found in residential and commercial buildings, they ensure sensitive devices are shielded from surges caused by lightning or switching operations.

Low-voltage arresters often use metal oxide varistors (MOVs) due to their fast response and effective clamping at lower voltages. They are usually installed at the service entrance or near critical equipment to prevent surges from reaching downstream devices.

Distribution arresters operate in medium-voltage power distribution systems, generally ranging from 3 kV to 10 kV AC. Their main role is to protect distribution transformers, cables, and power station equipment from transient voltage spikes.

These arresters can handle higher energy levels than low-voltage types and are often installed on power poles or substations. They typically combine MOVs and gas discharge tubes (GDTs) to provide both fast response and high surge current capacity. By protecting transformers and cables, they help maintain reliable power distribution.

These arresters are designed for high-voltage applications, protecting transformer station equipment and communication systems. They cover a wide voltage range from around 3 kV up to 220 kV or higher.

Station-type arresters usually consist of multiple valve elements made from metal oxide varistors arranged in series. This design allows them to handle very high voltages and large surge currents safely. They are installed at transformer terminals, switchgear, and other critical points in substations to shield expensive equipment from damaging surges.

Other specialized types include:

Magnetic Blow Valve Arresters: Used for communication systems and large transformers from 35 kV to 500 kV.

Neutral Protection Arresters: Installed on motor or transformer neutrals to protect insulation.

Signal and Communication Arresters: Protect data lines, coaxial cables, and communication equipment from surges.

Each type serves a unique purpose, offering protection tailored to the voltage level and equipment sensitivity. Proper selection and installation ensure effective surge suppression and system reliability.

Surge arresters protect electrical systems by responding instantly to voltage spikes. Normally, they act like an open circuit, letting electricity flow through the system without interference. When a sudden surge happens—caused by lightning or switching operations—the arrester detects the high voltage and quickly becomes conductive.

This change creates a low-resistance path that directs the excess current safely to the ground, preventing it from reaching and damaging sensitive equipment. The key to this function lies in components like the metal oxide varistor (MOV), which drastically lowers its resistance when voltage exceeds a certain threshold. This rapid response helps clamp the voltage spike to a safer level.

Gas discharge tubes (GDTs) also play a role by ionizing the gas inside when voltage surges, allowing current to pass through and diverting it. However, GDTs respond slightly slower than MOVs but can handle larger surge currents. Combining these components provides both fast reaction and high capacity to manage transients effectively.

The arrester’s ability to switch from non-conductive to conductive states during surges ensures normal operation continues unaffected, while high-voltage events are safely managed.

Surge arresters are installed at critical points in power systems, typically where conductors enter equipment like transformers or switchgear. They connect between the conductor and the earth ground, forming a protective shunt path.

By placing arresters close to the equipment, any transient voltage is diverted before it can cause harm. Often, surge arresters are installed at both ends of a conductor, especially in long transmission lines, to provide comprehensive protection against surges induced anywhere along the line.

In high-voltage systems, proper grounding is essential. The arrester must have a low-impedance connection to earth to ensure surge current flows away quickly and safely. Poor grounding can reduce the arrester’s effectiveness and increase risk to equipment.

Installation also considers system voltage, environmental conditions, and coordination with other protective devices. For instance, in distribution networks, arresters are mounted on poles or substations, while in low-voltage systems, they might be installed near service entrances or sensitive electronics.

Proper installation and maintenance ensure surge arresters perform reliably, extending equipment life and reducing downtime.

Clamping voltage, also called let-through voltage, is the key spec defining when a surge arrester activates. It’s the voltage level that triggers the arrester’s protective components to conduct and divert the surge. A lower clamping voltage means better protection, as it limits the spike voltage reaching your equipment. However, very low clamping voltages may reduce the arrester’s lifespan because it triggers more often.

For example, in a 120 VAC system, common clamping voltages are 330, 400, or 500 volts. If a surge protector has a 330 V clamping voltage, it will start diverting surges as soon as voltage exceeds that level. But if the clamping voltage is higher, some of the surge passes through, potentially stressing sensitive devices.

Joule rating measures how much energy the arrester can absorb without failing. It’s like the arrester’s “capacity” to handle surge energy. Higher joule ratings mean the device can withstand larger or more frequent surges. For instance, a surge arrester rated at 1000 joules can absorb more energy than one rated at 500 joules, offering longer-lasting protection.

Keep in mind, every time the arrester absorbs a surge, its protective components degrade slightly. Over time, the joule rating effectively decreases. That’s why regular inspection and replacement are important for maintaining protection.

Surge arresters must meet strict industry standards to ensure safety and performance. These standards define testing methods, performance criteria, and safety requirements.

Some widely recognized standards include:

IEC 61643 Series: Covers low-voltage surge protective devices, specifying requirements and testing for devices connected to power and telecommunication networks.

UL 1449: A key North American standard for surge protective devices, detailing performance and safety tests. The third edition introduced stricter testing and improved safety features.

ANSI/IEEE C62 Series: Defines surge protection requirements, including voltage ratings and test waveforms, focusing on power systems.

EN 61643: European standard aligning with IEC requirements for surge protective devices.

Compliance with these standards ensures that surge arresters can reliably protect equipment under real-world surge conditions. However, no standard guarantees perfect protection in every scenario. Engineers often perform specialized analysis to select and install arresters suited for specific environments, especially in high lightning risk areas.

Surge arresters play a vital role across both low and high voltage electrical systems. In low-voltage setups, such as residential or commercial buildings, they protect appliances, electronics, and transformer windings from voltage spikes. These spikes usually come from lightning or switching events. Low-voltage surge arresters commonly use metal oxide varistors (MOVs) because they react quickly and clamp voltage effectively at lower levels. They are often installed near service entrances or sensitive equipment, stopping surges before they cause damage.

On the other hand, high-voltage systems like power transmission lines and substations also rely on surge arresters. These devices handle much larger voltages and energy surges. Station-type surge arresters, made of multiple valve elements arranged in series, protect transformers and switchgear from transient overvoltages. They are installed at critical points where conductors enter equipment, diverting dangerous surges safely to the ground. This prevents costly damage and power outages.

Both low and high voltage systems benefit from surge arresters by maintaining equipment reliability and reducing downtime. Proper selection depends on system voltage, expected surge energy, and equipment sensitivity.

Surge arresters also protect communication systems, which often use sensitive electronics and long cable runs vulnerable to surges. Signal and communication arresters guard telephone lines, fax machines, modems, and data networks from transient voltages. These arresters prevent damage that could disrupt communication or data integrity.

Coaxial cable lightning arresters protect wireless transmission and receiving equipment, such as satellite receivers and mobile base stations. They use specialized designs to handle high-frequency signals while blocking surges. Fiber-tube arresters protect power station wiring connected to communication devices.

For communication systems, surge arresters must have low capacitance and fast response times to avoid signal distortion. Gas discharge tubes (GDTs) are common due to their low capacitance and high current handling, though they respond slightly slower than MOVs.

In summary, surge arresters are essential in communication infrastructure to prevent equipment failure, data loss, and service interruptions caused by electrical surges.

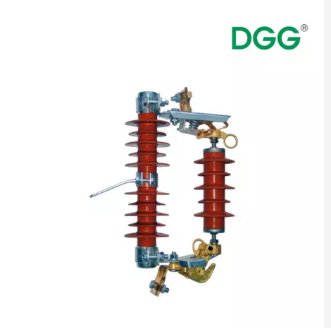

Surge arresters protect electrical systems from damaging voltage spikes, ensuring equipment longevity and reliability. They divert excess voltage safely to the ground, preventing damage from transients. As technology advances, surge protection will become even more efficient. Denggao Electric Co., Ltd. offers advanced surge arresters with unique benefits, ensuring optimal system safety and performance. Their products provide exceptional value, safeguarding both low and high voltage systems and communication networks from electrical surges.

A: Surge arresters protect power transmission line equipment from voltage spikes by diverting excess voltage to the ground, ensuring system reliability.

A: They prevent damage from transients, maintaining equipment longevity and reducing downtime in power transmission line equipment.

A: They protect against frequent transient events, preventing cumulative damage to power transmission line equipment.

A: Key components include metal oxide varistors, gas discharge tubes, and thermal fuses, ensuring comprehensive protection for power transmission line equipment.